Tales from the Road Part 2: Thailand

Thai Food and Culture

Recently I had the opportunity to travel to Southeast Asia and Australia to visit the global teams of one of our new clients, as well as tour/view their factories to see how we can make their implementation of Photoregister even more seamless. The trip was very educational, both on the different processes in global manufacturing, as well as on a personal level with all of the things I had the chance to do and see during the trip.

First Stop: Australia

On the fun side, when I arrived in Sydney at 9 a.m., I spent the rest of the day walking around the city and seeing some great things there, like the Opera house, Sydney harbor, botanic gardens, parks, St. Mary’s Cathedral, and then just the city itself. That night, I joined our clients at a rooftop restaurant that overlooked Sydney harbor, where we spent dinner getting to know one another even better. I spent the next day at their offices just outside Sydney where we did planning meetings surrounding the project with a focus on the IT implementations. Their IT manager is willing and able to help us in many ways and will be a huge benefit as we move forward.

Incentive Tests for Photoregister

Our client is working on a new implementation of Photoregister that will roll out in early 2017. The company is already planning an A/B/C/D incentive test to increase product registrations by placing a temporary sticker on the front of one of their products, which will include a Photoregister icon. Phase 1 will be instructions on where to find the Photoregister icon on the serial tag, but Phase 2, likely around April 2017, will have the Photoregister icon included on the main product sticker – in addition to the serial tag – for maximum visibility.

This kind of testing is really helpful for our clients to see the types of response they will get with placing the Photoregister tag in different locations.

Aussie Factory: What We Did

The company’s factory in Australia is slightly different from what we have seen previously, which is the main reason I have been traveling to them. Rather than having a print shop that creates the carton labels and serial tags for all of the products being produced in advanced, this factory used dynamic printing on the line to create both the carton label and serial tags. It’s a more fragmented system, but print-on-demand means less concern over organizing print materials and making sure they end up tied to the correct product.

Kangaroo for Dinner

On the second night, we again had a nice dinner with the whole team, including two new members who worked at the production facility. We went to a restaurant right off the river and I had Kangaroo for the first time. It was pretty gamey, but similar to venison really.

The next stop after Australia was a couple of days being a tourist in Thailand, where I explored the city. Watch for my next post covering my time in Thailand as well as my visit to Rayong to visit another factory.

Stay Tuned.

New York City -- It’s always fun to speak to customers, especially when the conversation is unexpected. The other day I was being interviewed by...

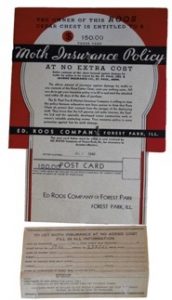

The headline captures my eyeballs: “$150 Moth Insurance Policy at No Extra Cost.”